How do we provide the service?

A novelty in our market is the service of furniture construction and technical preparation in interior design. We make drawings in CAD/CAM software – MegaCAD/MegaTISCHLERpro.

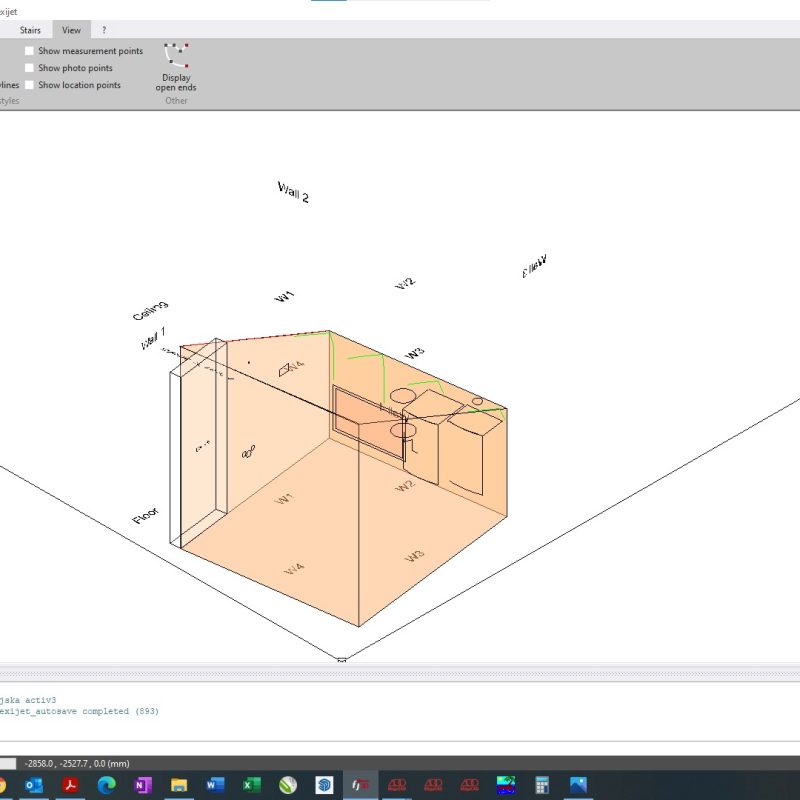

After a detailed 3D measurement, the construction of custom-made furniture and interior design with the CAD/CAM program comes to the fore.

TECHNICAL PREPARATION SERVICE INCLUDES INDIVIDUAL ITEMS OR ALL TOGETHER:

- Space measurement

- Furniture construction

- Construction of interior equipment

- Making 2D/3D sketches of workshop drawings

- Making characteristic details

- Cost calculation – material consumption and working hours

- Order materials and fittings

- Making a cutting list

- Programs for CNC machines (Homag/Weeke, Biesse, SCM…)

WITH MEGACAD SOFTWARE YOU CAN:

- draw rooms of the desired shape (rooms, apartments, buildings…),

- fittings, pieces of furniture,

- furniture, carpentry, cladding, as well as other elements of furnishing the space,

- place furniture and other elements of furnishing the space in the drawing of the room,

- archive drawn furniture and other elements of furnishing the space for later quick and easy insertion into the new space, make and quote technical drawings of furniture,

- carpentry, as well as the entire equipped space, see the equipped space (zooming in / out, turning the view, “walking” through the space,…)

Watch our video on reducing work errors

IN GENERAL, MEGACAD IS A CAD SOFTWARE FOR:

MegaCAD is a general CAD program for 2D construction and 3D modelling

simple 2D technical drawing in a plane (line, circle, ellipse, arc…),

quick and easy design of 3D geometric bodies (square, roller, cone, pyramid, ball, rotating body, pull-out body, sum of bodies, body difference, body cross-section…),

automatic creation of 2D technical drawings from 3D bodies (draft, floor plan, side view, section, detail…),

quick and easy equipping of technical drawings (elevations, descriptions, notes, frames, components…),

Applicable in all technical professions (architecture, construction, mechanical engineering, final wood processing…),

MegaCAD is compatible with all other existing CAD programs. Thus, it basically includes import/export of the filters for the following file types: DWG, DXF, CDL, 3DS, SAT, VRML, and at the request of the user additionally VDA-FS, IGES, STEP, CATIA, Pro/E and STL.

WITH MEGATISCHLERPRO CAM SOFTWARE YOU CAN:

The MegaTISCHLERpro software package is an upgrade to the MegaCAD 3D software package.

From MegaCAD closed 2D contour MegaTISCHLERpro forms a 3D element and fits into the product design

furniture can be designed/constructed quickly and easily (kitchen elements, beds, built-in cabinets, chests of drawers, piece furniture…,

we can quickly and easily complete furniture (fasteners/dowels, connectors/eccentrics, hinges/couplings, legs, handles, shock absorbers, dampers, drawer guides, locks…).

Wide application in interior design (wall coverings, partition and sliding walls, shower and toilet cabins, receptions, laboratory furniture, period furniture, pharmacies…)

the application of the MegaTISCHLERpro program for fast furniture construction and production preparation is not limited to panel materials and furniture.

Except for wood materials (plywood, chipboard, MDF, compact boards, panels of length and width glued solid wood, veneers, slats…), the same procedure can be equally effectively applied to non-wood materials (aluminium, steel or plastic profiles, glass, mirrors , sheets…).

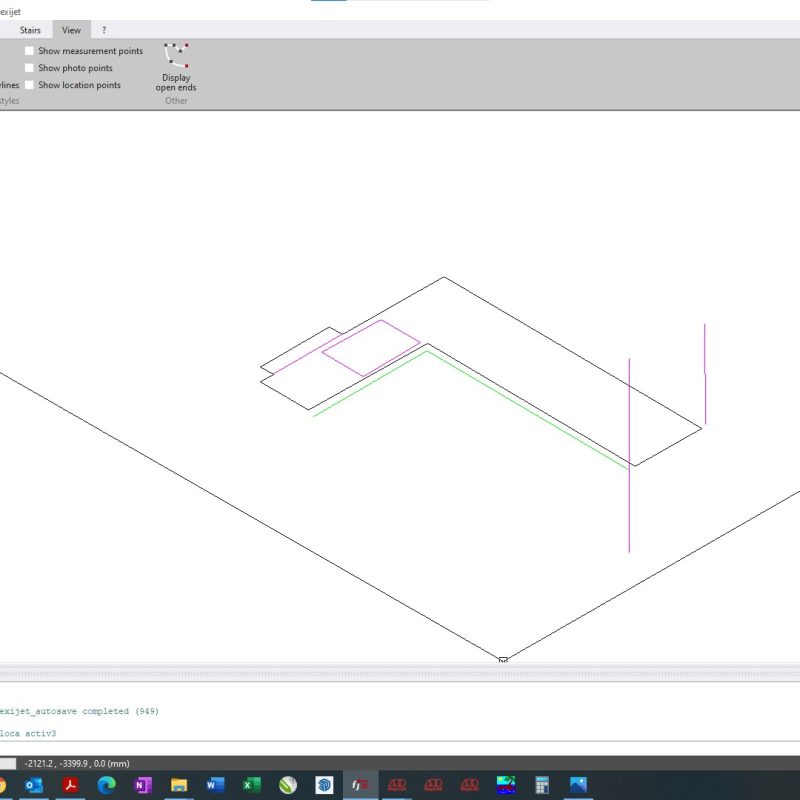

In combination with FLEXIJET, the goal of these programs is to increase production productivity, speed up the process from idea to realization, and reduce the possibility of errors.

Everything else needed for sales, procurement and production (including programs for CNC machines), MegaTISCHLERpro will do by itself.

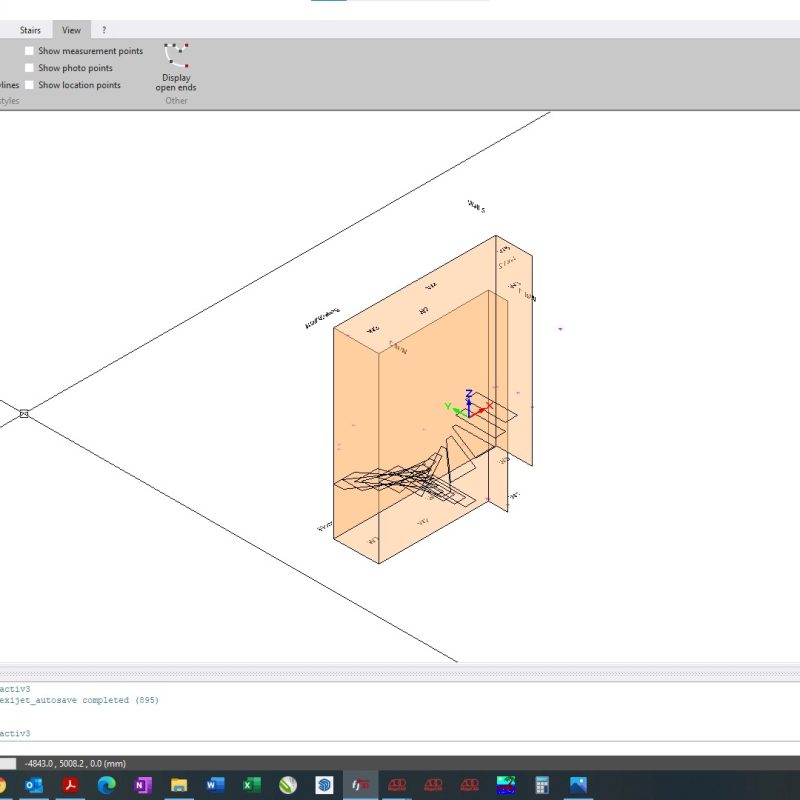

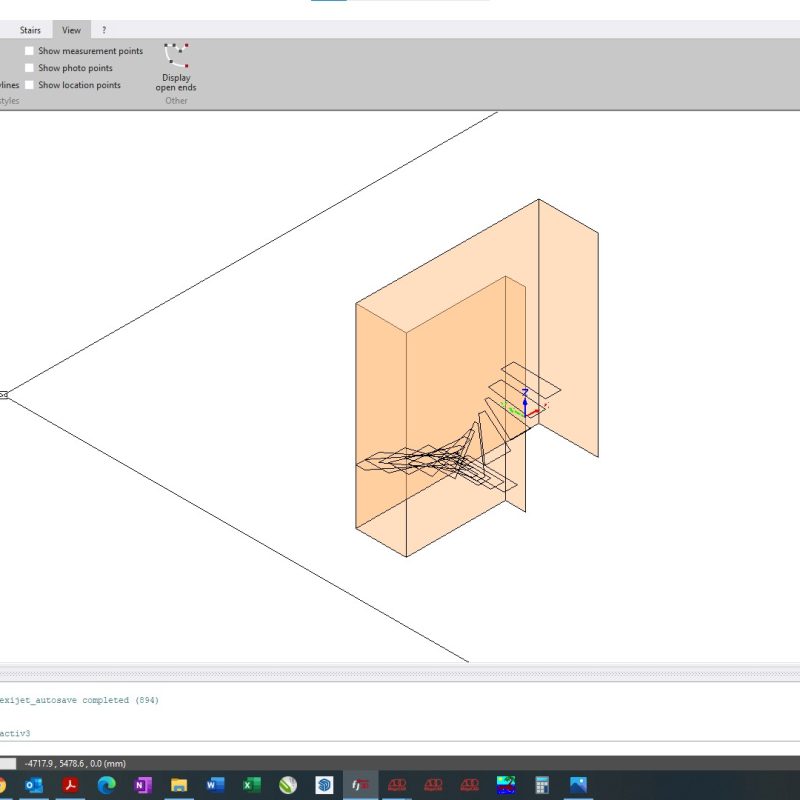

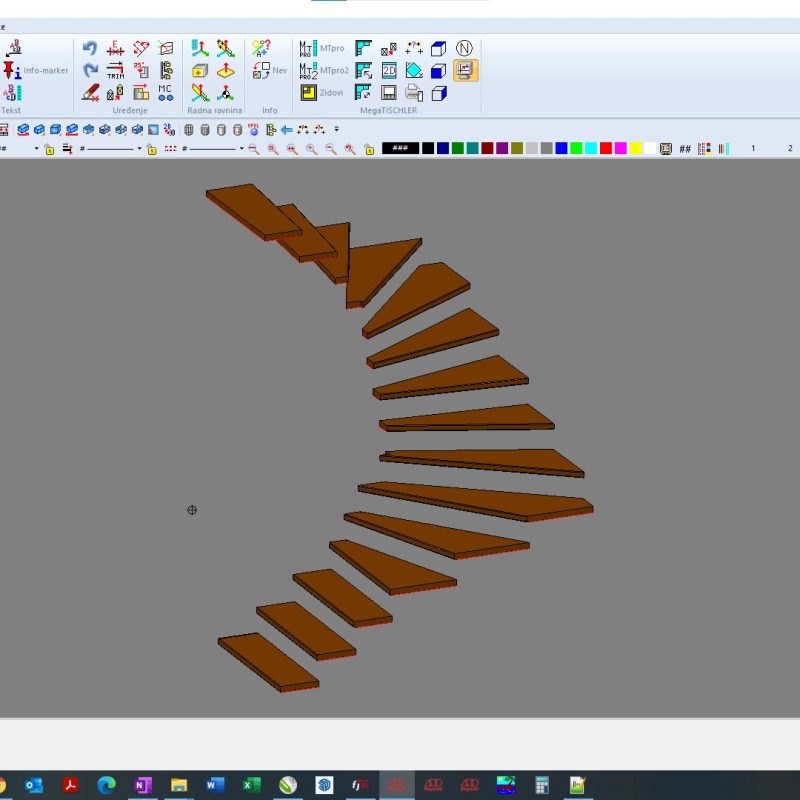

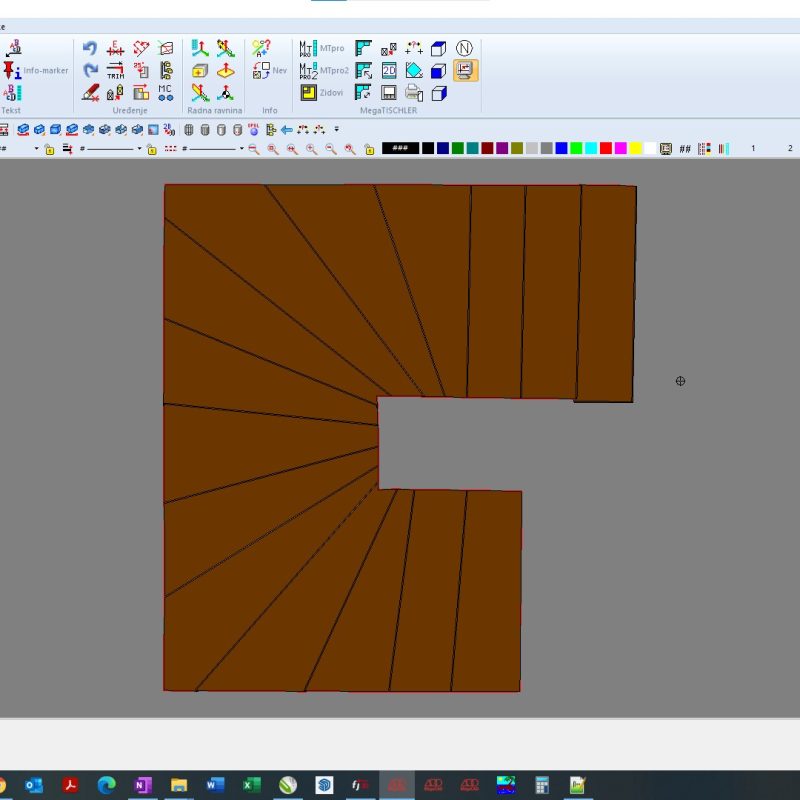

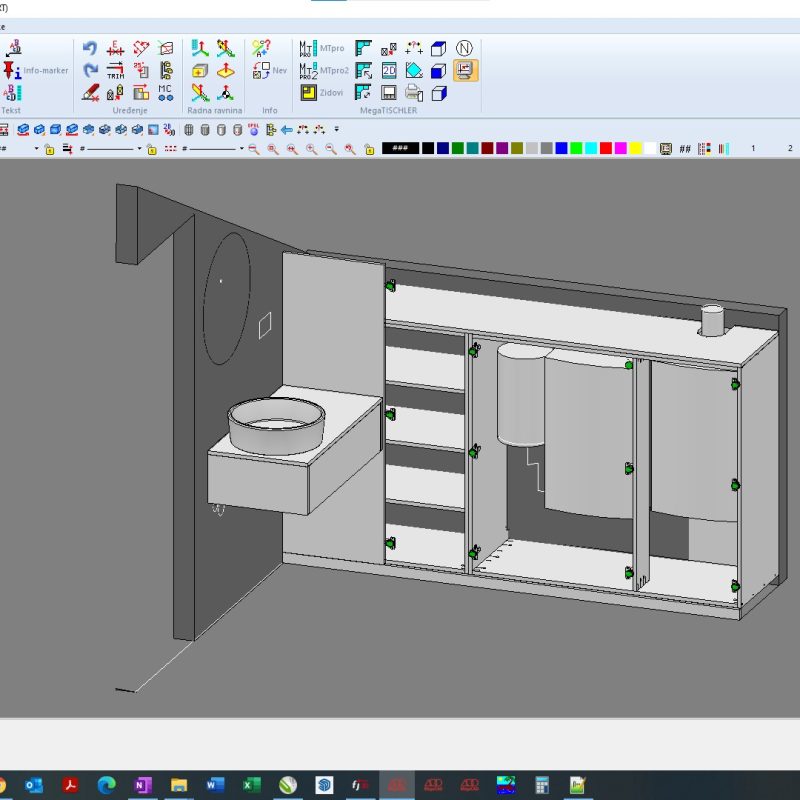

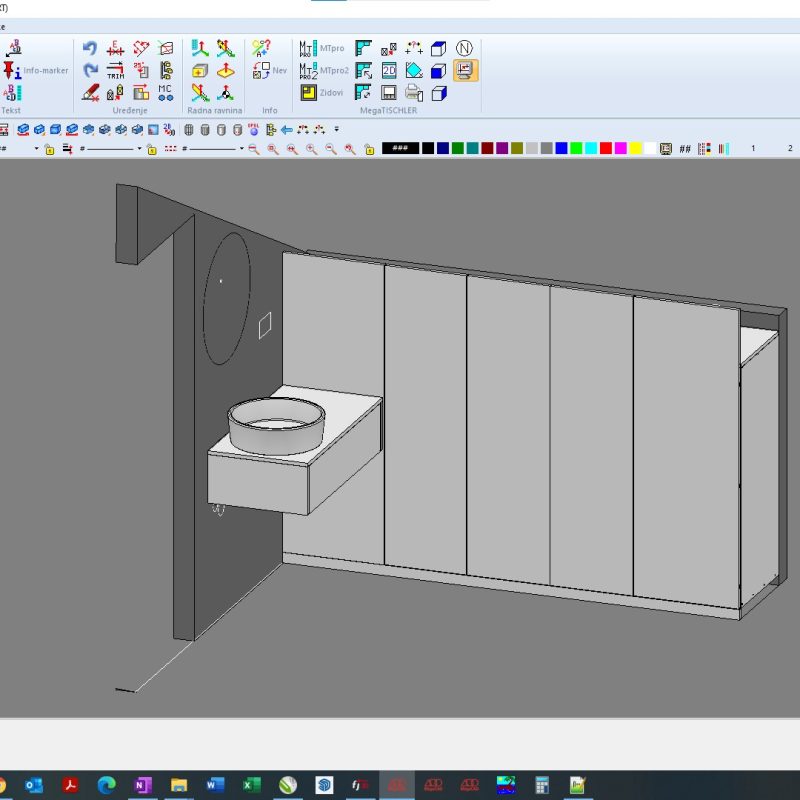

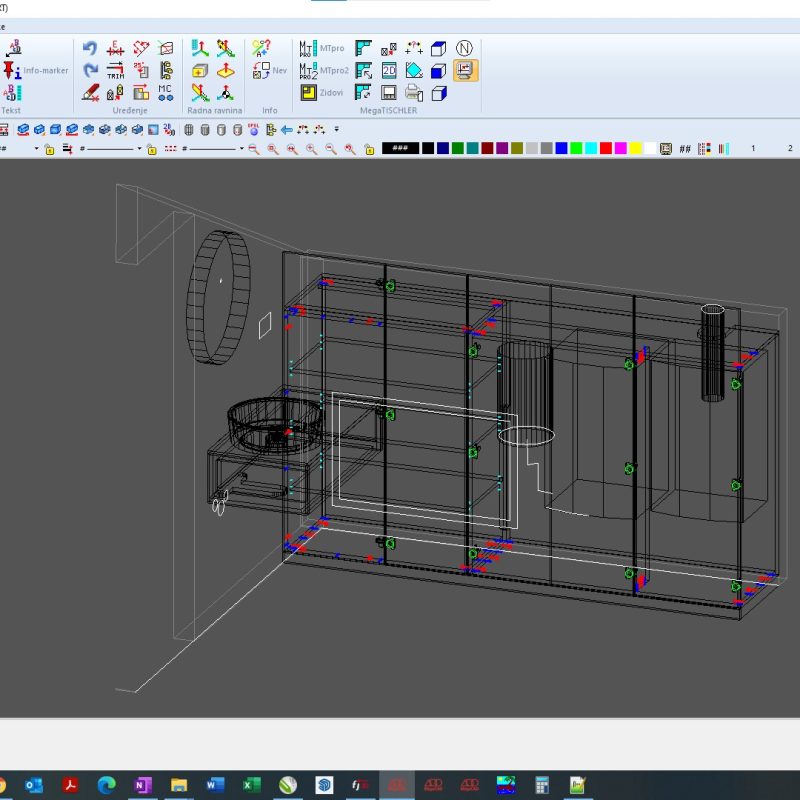

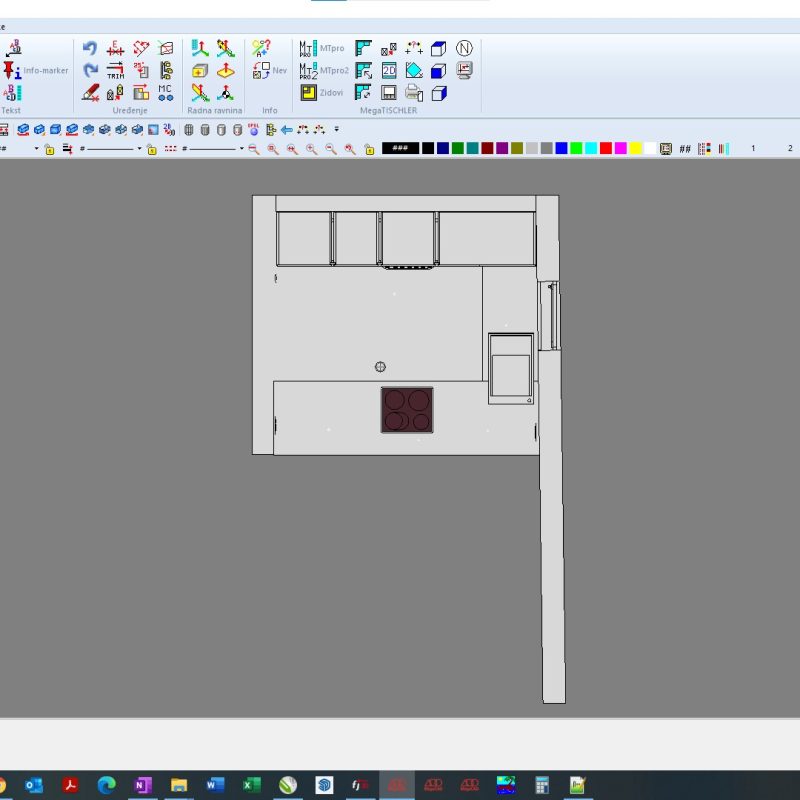

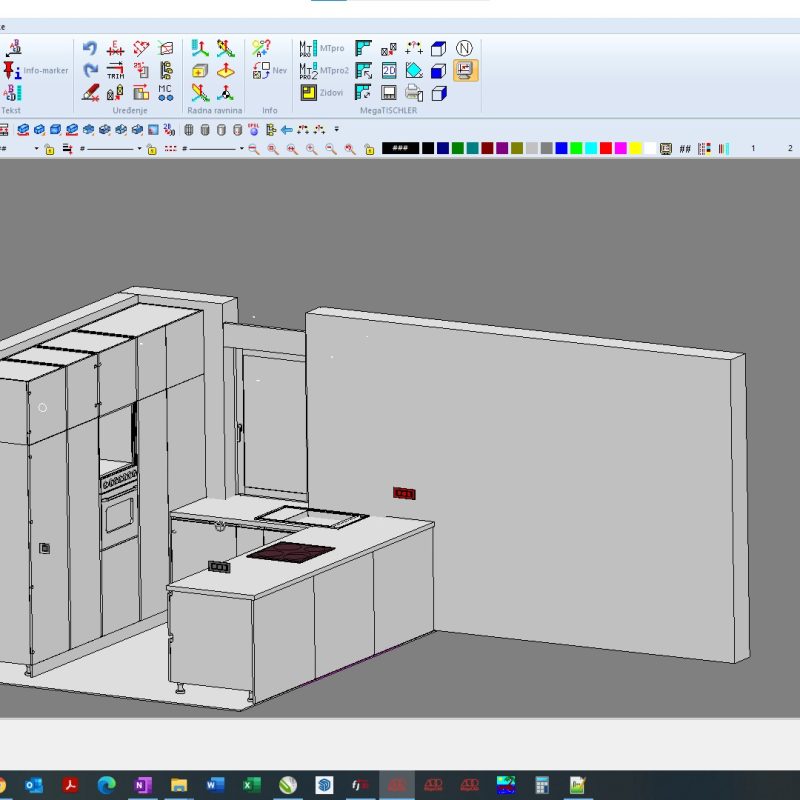

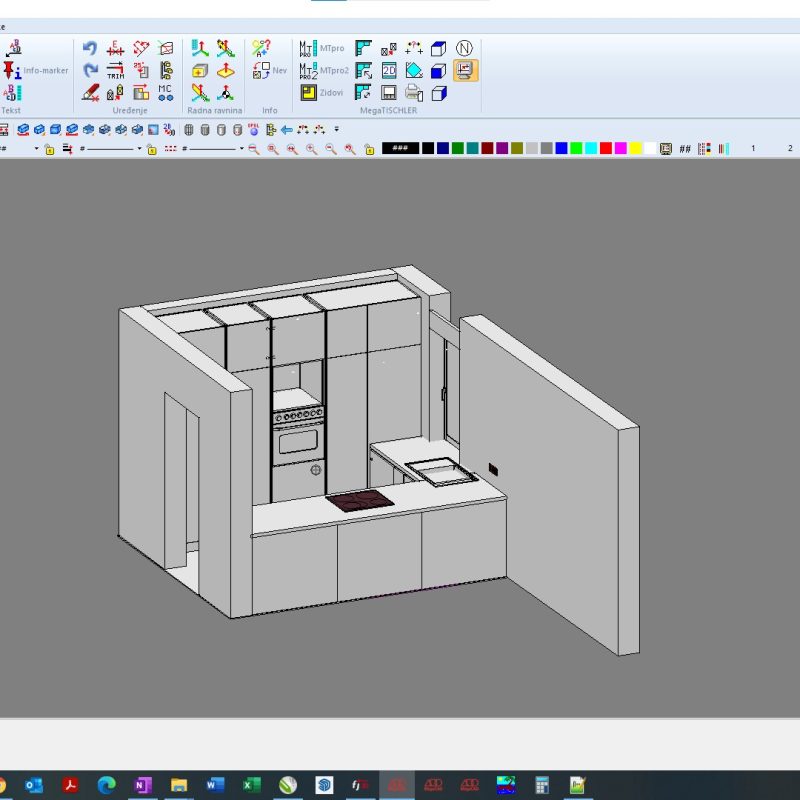

Project example: object measurement and position for interior equipment

After the measurement, and according to the obtained measures, we started the construction of furniture and technical preparation for the production of furniture.

Complete furniture is made on CNC machines.

All operations from cutting materials, drilling, milling cut-outs at valve locations, milling cut-outs on worktops, worktop joints are done in the workshop.

The fitters only have to bring minimal tools and assemble the furniture on site.

Check out the photos below (click on the images to view larger dimensions):